ELİT TRAIN WASH T7

BRUSHED TRAIN TRAM WASHING MACHINEGeneral Features

Design

Technology

Usage Areas

The Q WR 9 series with 6 brushes, 3 mt washing height and 2.60 mt washing width, is produced for settlements such as municipalities, bus fleets, parking lots, gas stations, etc.

The Q WR 9 series with 6 brushes, 3 mt washing height and 2.60 mt washing width, is produced for settlements such as municipalities, bus fleets, parking lots, gas stations, etc.

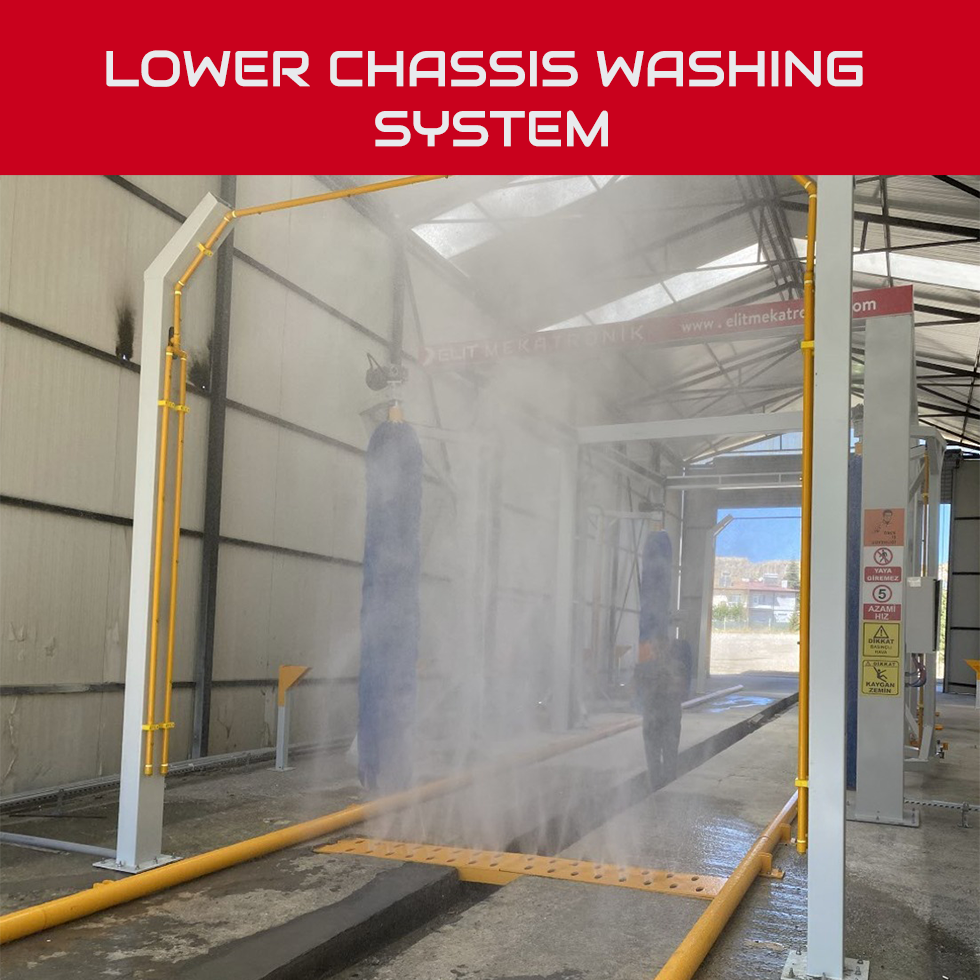

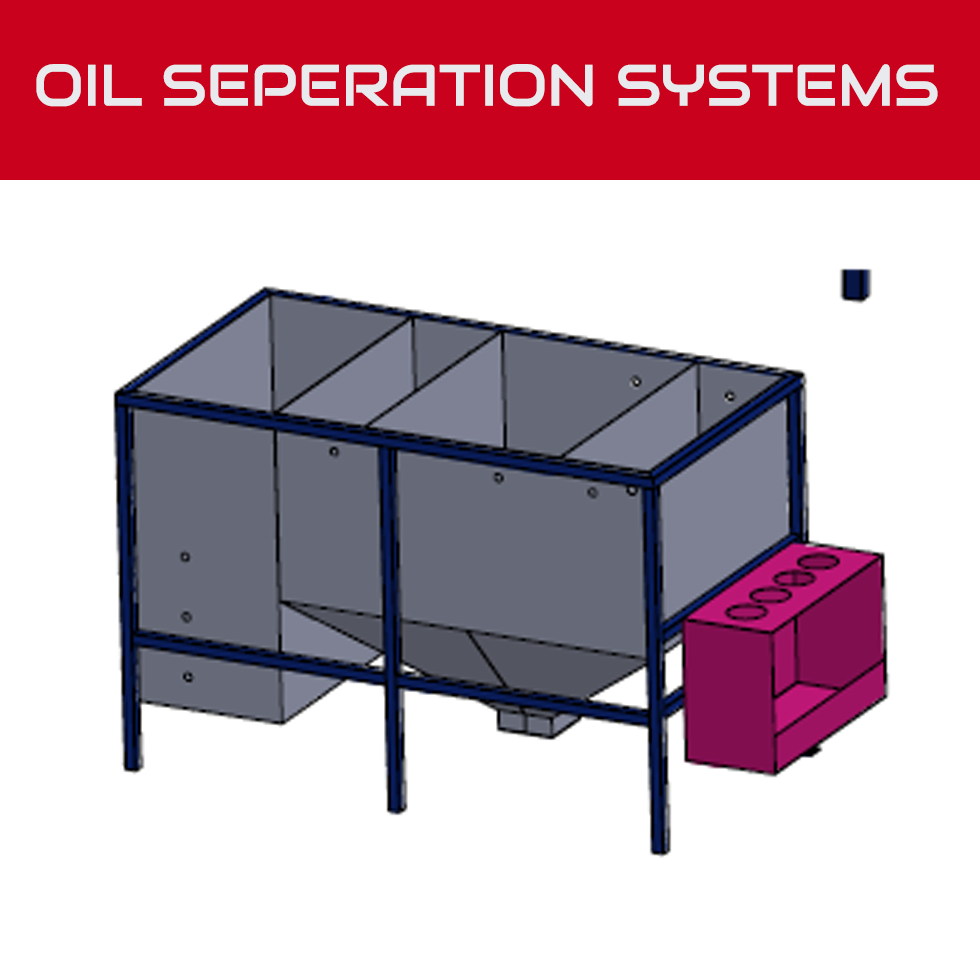

Optional Products

In addition to sub-chassis washing, rim washing, pressure side wheel washing, foam, polish, disinfectant and drying system, it offers professional washing service with preferable technological design.

In addition to sub-chassis washing, rim washing, pressure side wheel washing, foam, polish, disinfectant and drying system, it offers professional washing service with preferable technological design.

Pioneering Design Model

QR 9 series, which has 6 different washing options with a TFT 7-11 inch color screen with Pofinet connection, also has each unit disabled and commissioning fault warning system, fault codes and central help connection option on the screen.

QR 9 series, which has 6 different washing options with a TFT 7-11 inch color screen with Pofinet connection, also has each unit disabled and commissioning fault warning system, fault codes and central help connection option on the screen.  Thanks to the TFT color screen on the remote or control panel, it has instant and daily car washes, separate electricity, water, foam, polish and drying unit consumption information menu.

Thanks to the TFT color screen on the remote or control panel, it has instant and daily car washes, separate electricity, water, foam, polish and drying unit consumption information menu.

Technical Data

- Max vehicle height: 4500

- Max vehicle width: 2500

- Rail length: 21.000 – 27,000

- Rail width : 2800

Consumption Information

- Number of shampoo and polish nozzles – 10-18 nozzles, 6.70 L/min 1.45 gpm 3 bar 48.5 psi

- Number of water rinse nozzles: 6-24 external long nozzles 23.5 l/min 6,734 gpm 3 bar 48.5 psi

- Air pressure 6 Bar – 10 lt /min

- Number of brushes and consumption: 2 rear left and right 1 front wash 1 upright 2 skirts

- Electric installed power and consumption: 50 kw 380 / 50 Hz 0.30 kw electricity consumption 1 car wash

- Water pressure and consumption: 3 bar – 650 lt / min

- Washing time: 1-3 min / vehicle